Under the booming development of today's electric power industry, the traditional management mode has been difficult to meet the demand for efficient and reliable management and operation of substations. The high operation and maintenance cost, untimely fault warning, and insufficient data analysis ability of substations are becoming more and more obvious, which seriously restricts the further development of the industry. Substations need to break through the limitations of the traditional management mode, so the substation twin system brings a solution for substations. Through real-time monitoring and early warning functions, the substation twin system can detect potential faults in time, improve the safety of substations, and optimize the operation and maintenance process with the help of powerful data analysis and intelligent decision-making support, which truly realizes the optimization of substation management and the efficiency of operation and maintenance.

Substation Twin System

The substation twin system monitors the operation status of core equipment in real-time, predicts problems that may occur during the equipment operation cycle, and then carries out maintenance and repair in advance; analyzes historical and real-time equipment data to optimize the operation strategy of the substation; and simulates the operation trend of the substation to provide references and optimization suggestions for the operation of the actual substation, which ultimately achieves the improvement of the operation efficiency and economic benefits of the substation. Enhancement.

The substation twin system built based on Lithium-volt-J3D low-code digital twin platform utilizes advanced digital twin technology to conduct real-time dynamic monitoring of substations, realizing the functions of equipment status visualization, intelligent fault warning, automation of data collection and processing, etc. It improves the operational efficiency, reduces the maintenance cost, and provides a strong guarantee for the stable operation of substations. At the same time, the system also supports a variety of data interface access, can be seamlessly docked with other management systems to achieve data sharing and collaborative management.

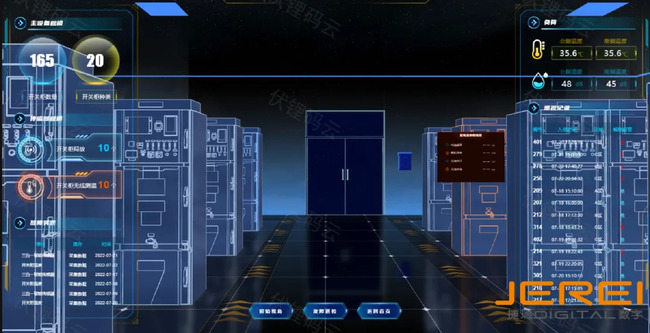

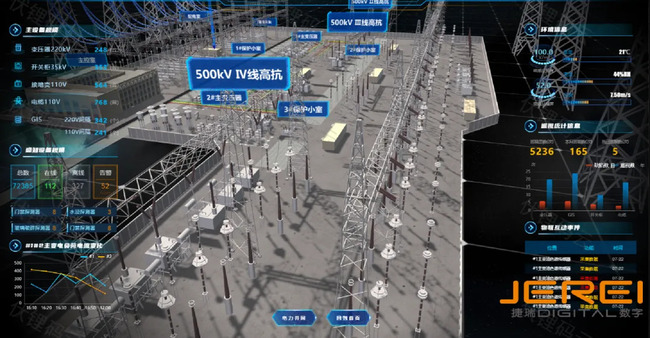

Visualization of equipment status: “One screen to see the whole field” Showing the workshop in all directions

Substation twin system through the digital twin technology and the physical transformer three-dimensional modeling, effect debugging and other means will be in the virtual environment for three-dimensional restoration, and on-site cameras, intelligent sensors, central control system, management information and other sources of heterogeneous data real-time reading and processing, through the equipment protocol, data format and data platform, the collection of all data sources of data aggregation, and will be the big data platform, Data Center, sensors and other locations to capture the data information pushed to the twin platform.

Within the twin substation scene, real-time data information is superimposed on the transformer to display, while the platform acquires the operation data, index data and business-related data of each system in real time and presents them intuitively, so that the virtual three-dimensional world replicates the physical world, forming a real-time situational awareness capability, and forming BI reports, curve diagrams, line graphs, and so on.

Managers can view and capture equipment data and information through clicking interaction, realizing real-time monitoring of equipment operation status.

Intelligent Fault Warning Accurately locate fault points and improve maintenance efficiency

The substation twin system monitors and analyzes transformer operation data in real time to ensure its stable operation and effectively prevent power interruption and equipment damage caused by faults. The system captures abnormal fluctuations in substation operation data, quickly identifies potential equipment faults, sends out corresponding alarms and locks the fault point according to the fault level, which helps operation and maintenance personnel to quickly carry out maintenance work, significantly shorten the downtime, improve maintenance efficiency, and discover potential equipment faults and hidden dangers in a timely manner, avoiding economic losses due to equipment failures.

Data Acquisition and Processing Automation Large amount of data combined with adaptive algorithms

The substation twin system collects a large amount of data from transformers in the substation and conducts more in-depth mining and analysis, combining the big data platform and expert algorithms to provide optimized analysis choices and realize the status monitoring of the transformer in the whole process.

Real-time status

Through real-time data collection, it shows the real-time running posture of the transformer, realizing millisecond-level real-time status presentation;

Historical state

Through the storage and retrieval of historical data, realize the review of historical data and observe the historical operation data of transformer;

Prediction state

By docking the prediction function of the big data platform, the prediction process is viewed in three-dimensional form, supporting fault prediction and life prediction display.

Fulima cloud platform Digital twin-driven industrial Internet platform

Fulima cloud platform is a service-oriented manufacturing demonstration platform recognized by the Ministry of Industry and Information Technology of the State, is committed to digital technology, effectively help enterprises based on manufacturing, into the service, improve manufacturing efficiency and product service capabilities, reshape the manufacturing value chain, and promote the transformation of manufacturing enterprises to service-oriented manufacturing.

The platform includes J3D digital twin development platform, RBI business intelligence development platform, model intelligence lightweight platform and application low-code development platform, supporting online development of Web digital twin and digital decision-making applications. At the same time, the platform builds an open industrial Internet technology service system, covering a series of products and technology solutions such as Internet of Things, data platform, digital twin application development, algorithm services, etc., to create an industrial Internet industrial ecology with abundant resources, information sharing and win-win cooperation, and to help enterprises in the digital transformation and upgrading of the whole value chain from the three dimensions of digital marketing, digital production, and digital management and control.

Our Official WeChat

Our Official WeChat