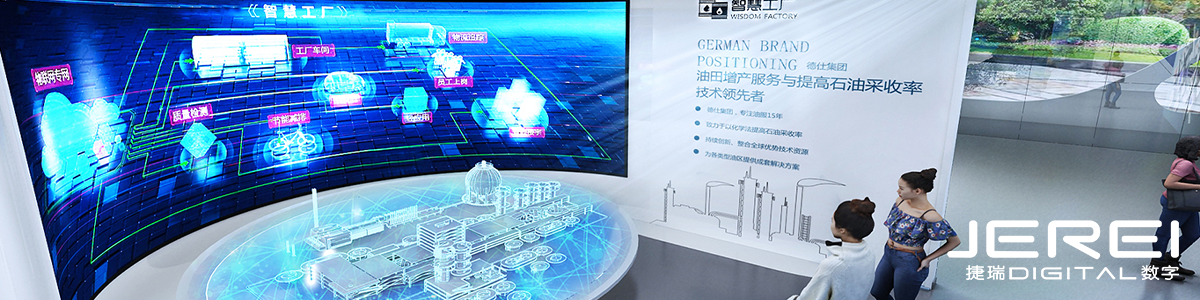

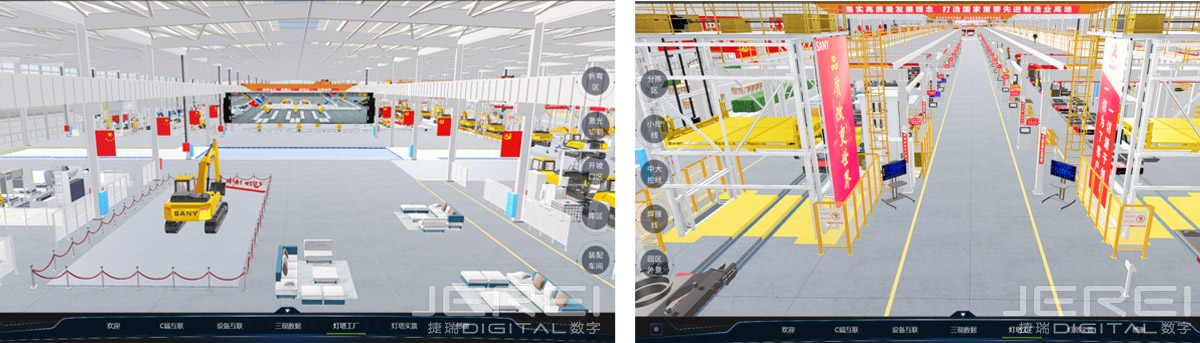

Users can rotate, zoom and move the whole park through keystrokes and mobile tablets, and can also customize roaming routes through route setting and parameter configuration (speed, height, pitch, voice, text, etc.) in the scene, and the roaming routes can be automatically guided, and the first and third-person viewpoints can be freely switched. Roaming can be presented in PC, VR and mobile. Help users better control the site production.

Based on the three-dimensional model, the use of data fusion, presentation technology, presented in the form of a variety of charts, to achieve the whole elements of the production workshop, the whole process, the whole business of the integrated control, to help managers to be able to accurately find, accurate scheduling, real-time monitoring and control of the process, to improve the efficiency of the management, to reduce the intensity of labor, so that the workshop management of digitalization, intellectualization, transparency.

Based on 3D modeling and fusion of multi-source data, the historical data is viewed retrospectively in the form of 3D animation, and the scene playback includes functions such as fast forward, slow playback and pause. It provides data support for on-site problem solving and improves the problem solving rate as well as the problem closing rate.

Through the built-in powerful data retrieval module, it realizes data query function, including but not limited to model, equipment, AGV, production order, material, process worker details, single worker work efficiency analysis and other queries; it supports fuzzy search, full-text search, combined query and precise query, etc. After querying, the 3D model, spatial information, business data, etc., can be highlighted and positioned. It helps managers to quickly find and query information to improve management efficiency.

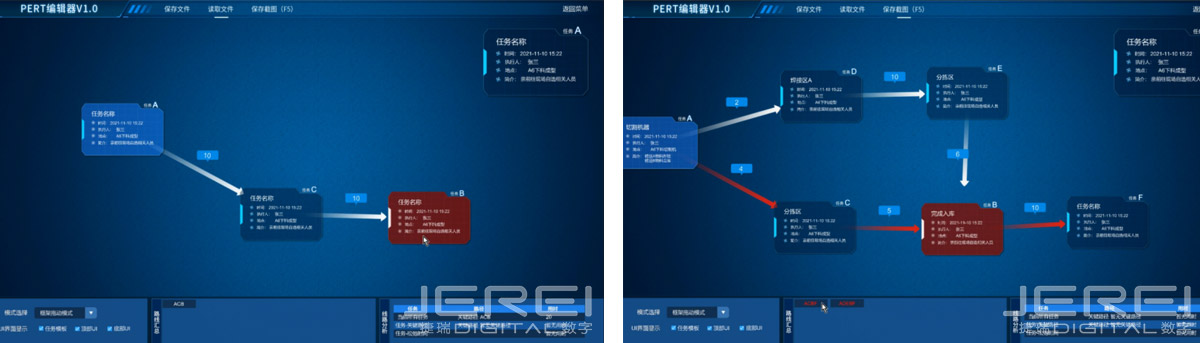

Through the establishment of the corresponding task model, simulate the production status quo, through the algorithm to calculate and present the accessibility of manual workstations.

Through the manual accessibility analysis, we can calculate the corresponding order fulfillment rate, the fatigue degree of manual workstation and the analysis of manual work energy consumption, etc., which can help the managers to arrange the tasks and plan the operation steps rationally.

By expressing each operation process and their interrelationships with PERT diagrams, on the basis of which network analysis and time estimation are performed. Taking time as the center, we find out the longest route from the start to the completion of the time needed, and plan the system around the key route, rationally arrange as well as closely control the progress of the completion of each job, so as to achieve the completion of the system's predetermined goals with the least amount of time and resource consumption.

Guangxi LiuGong Digital Pavilion Digital Twin Factory application is built based on real factories, realizing real-time data-driven virtual factories, perfectly integrating the core technologies of virtual-reality mapping, synchronization, symbiotic evolution and closed-loop optimization. Through integrated control, it helps enterprises complete digital and intelligent transformation. Powerful data query function supports multiple query methods to quickly locate information and improve management efficiency. Artificial accessibility analysis function helps enterprises optimize task allocation and operation steps, and roaming workshop inspection through keyboard and mouse, mobile tablet, realizing all-round control of the production site.PERT editor helps enterprises carry out network analysis and time estimation, realizing optimal allocation of resources.