Introduction

With the implementation of the dual-carbon target and the increasingly tense global energy environment, energy costs continue to rise, and enterprises are facing increasing pressure on energy costs. Therefore, reducing energy consumption and lowering energy costs has become an urgent problem for enterprises. However, the traditional energy management and control methods lead to production energy consumption and single product costs can not be clear, and various types of energy data is relatively independent, enterprises need to take a more accurate and intelligent way to manage energy use.

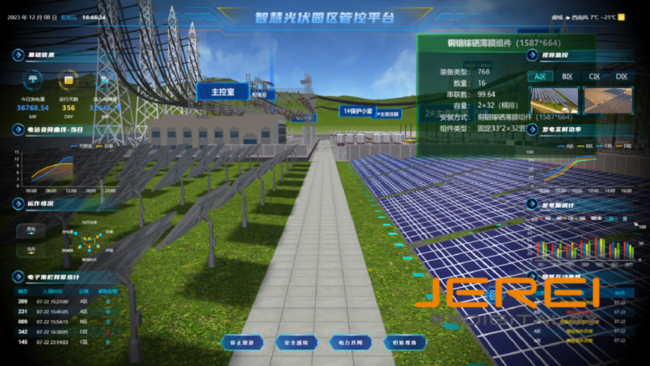

The construction of a new energy digital twin integrated control platform to achieve the full life cycle control of energy (conventional energy and new energy), unmanned intelligent operation and maintenance, rational scheduling, through the collection and analysis of energy consumption data, to formulate energy saving and consumption reduction of continuous optimization of the program, and ultimately to achieve the improvement of the level of energy management, reduce energy consumption, energy saving and emission reduction, and to help the “dual carbon” goal to achieve. “Double Carbon” goal realization.

Energy Monitoring Real-time Monitoring and Abnormal Alarm

The energy control system realizes the centralized management of energy digital twin system by monitoring and managing the whole energy chain (such as power distribution, new energy sources, cooling and heating sources, energy storage, air conditioning, lighting and other systems), and real-time monitoring and abnormal alarms for the supply, consumption and environmental (temperature, humidity, etc.) information of each energy sub-system.

New Energy Operator

Provide a unified data monitoring platform to fully grasp the operation and consumption of water, electricity, gas and heat on the user side in real time, and accurately push the alarm information of the monitoring equipment on the user side and quickly locate the equipment failure.

Energy Consumption Customers

With the information collection of energy equipment, energy users can grasp the operation status of their own equipment and energy consumption in real time; provide professional monitoring team for energy users to ensure the monitoring quality of energy equipment and save the labor cost of operation and maintenance.

Intelligent operation and maintenance Enhance the efficiency of operation and maintenance work

Based on equipment status and operation monitoring data, the system is able to discover equipment faults in time, reasonably formulate equipment operation and maintenance plans, monitor the execution of operation and maintenance work in the whole process, improve the operation and maintenance support system, improve the efficiency of operation and maintenance work, and reduce the impact of equipment faults, so as to provide intelligent operation and maintenance services for the users, and ultimately realize unmanned operation and maintenance.

Energy Efficiency Analysis: Accurate Diagnosis, Cost Reduction and Efficiency Improvement

Combining energy consumption data and equipment operation data, the system generates energy analysis reports through network loss analysis, peak and trough analysis, same ring comparison analysis, trend analysis, etc., which helps enterprises discover abnormal points of energy consumption in a timely manner, and helps them to continuously optimize and adjust energy consumption.

Energy Consumption Early Warning Precise Positioning and Multi-Level Early Warning

Through real-time analysis of energy consumption data and comparison with preset energy consumption indicators, once abnormalities are found, the system will immediately notify the relevant responsible person through SMS, WeChat, APP push, email and other means, and urge follow-up of the results. In addition, the system will also remind in the three-dimensional scene or energy flow diagram in a red eye-catching way, to assist in rapid and accurate positioning, and improve the efficiency of problem identification.

Energy Simulation New Energy Digital Twin Integrated Control Platform Trend Modeling

Combined with the enterprise energy physical system to carry out mechanism modeling, through the multi-energy trend calculation, energy station equipment capacity configuration, multi-energy system economic operation analysis, multi-energy N-1 calibration, weak link analysis, to guide the operation of the enterprise's new energy digital twin integrated management and control platform.

Energy Regulation Integrated Energy Dispatch Optimization

Based on the energy system model and optimization control algorithm, the system formulates energy optimization and control strategies, and schedules the operation of various energy subsystems in accordance with economic, green, and comprehensive control strategies.

▲The optimization strategy control of the new energy digital twin integrated control platform (PV-heat pump-water cooled unit-ice storage cogeneration system) as an example.

Carbon Neutral Analysis All-round Carbon Footprint Management System

The system builds a scientific carbon emission monitoring index system, realizes all-round monitoring, benchmarking and diagnosis of carbon emission in the enterprise; carries out research on carbon emission reduction methodology, conducts operation and management of carbon assets, assists users to formulate emission quotas, adjusts energy use structure and improves energy efficiency.

Real-time carbon emission flow monitoring

Multi-dimensional carbon emission flow analysis

High-accuracy carbon emission flow prediction (build carbon peak and carbon neutral roadmap for enterprises, and timely warn of carbon emission overruns)

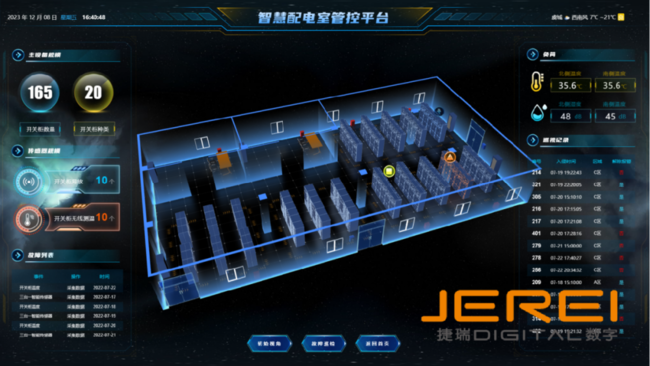

Digital Twin Visualization One Screen Visibility, One Screen Management

Construct equipment-level twin model, combine energy data to realize data fusion, combine twin model, centralized monitoring and management of equipment and facilities to realize one-screen visibility and one-screen unified management.

Data fusion, full-area sensing

Construct device-level twin models, combine various types of data to form twin relationship maps, and realize data fusion.

Centralized monitoring and fine management

Combine the twin model to centralize monitoring and management of equipment and facilities to reduce energy costs and improve energy quality.

Simulation and Prediction, Interactive Coordination

Construct simulation and prediction model to improve the coordination ability of source, network, load and storage, and provide decision-making support for the interaction of source, network, load and storage.

Digital twin-driven industrial internet platform

The energy control system is built on the R&D base of Voltron Cloud Platform, which is a service-oriented manufacturing demonstration platform recognized by the Ministry of Industry and Information Technology of the People's Republic of China. It is committed to effectively assisting enterprises to base on manufacturing and integrate into services through digital technology, improving the manufacturing efficiency and product service capabilities, reshaping the manufacturing value chain, and promoting the transformation of manufacturing enterprises into service-oriented manufacturing.

The platform includes J3D digital twin development platform, RBI business intelligence development platform, model intelligence lightweight platform and application low-code development platform, supporting Web digital twin, digital decision-making application online development. At the same time, the platform builds an open industrial Internet technology service system, covering a series of products and technology solutions such as Internet of Things, data platform, digital twin application development, algorithm services, etc., to create an industrial Internet industrial ecology with abundant resources, information sharing and win-win cooperation, and to help enterprises in the digital transformation and upgrading of the whole value chain from the three dimensions of digital marketing, digital production, and digital management and control.

Our Official WeChat

Our Official WeChat