Introduction

Workers can complete the textile workshop inspection through the big screen, do not have to walk around the workshop frequently;

Production data and analysis only need a big screen to be able to see the whole picture, managers do not have to cross-departmental tracking;

Real-time monitoring and warning of key data anomalies, reducing the risk of corporate attrition;

......

In Weiqiao Digital Twin Green Intelligent Dyeing and Printing Factory, the production, operation and management of the park can be digitized and upgraded with intelligent transformation.

Digital Twin Green Intelligent Dyeing and Printing Factory

With the environment driving the upgrading of the whole industry chain, consumers driving the improvement of efficiency and quality, and sustainable development driving the intelligent and green development, traditional industries need digital transformation to enhance competitiveness and market share.

To this end, Weiqiao Digital Twin Green Intelligent Printing and Dyeing Factory, built on Fulima Cloud Platform, carries out comprehensive, efficient and accurate monitoring and management of human, machine, material, method, environment and measurement information in the production process through digital twins, Internet of Things, big data, artificial intelligence and other technologies, so as to optimize the production process, improve the production efficiency and product quality, significantly reduce the cost and energy consumption, and successfully build a Intelligent, digitalized printing and dyeing factory.

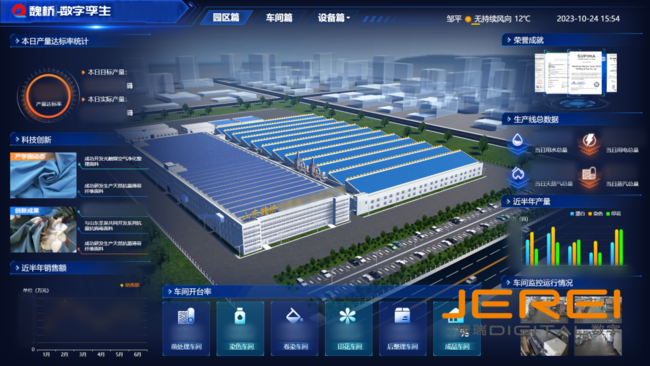

Digital twin 1:1 restoration A glimpse of a screen and know the whole factory

In the printing and dyeing factory, the virtual simulation printing and dyeing production line equipment are running in an orderly manner, and the production line data are updated in real time through visualization reports on the big screen. This is a digital twin green intelligent printing and dyeing factory built by Fulima cloud platform based on digital twin engine, in accordance with the printing and dyeing production process, process flow, 1:1 real restoration in the virtual space, which realizes the twinning of the entire factory park, printing and dyeing production lines, production line production equipment at all stages of the twin presentation, and for the production process of the equipment operating mode to complete the corresponding model animation, real-time presentation of the operating state, realizing two-way real mapping of reality. The staff can monitor the status of the production line twins on the big screen and realize the comprehensive scheduling and control of the whole production process with the data changes.

Breaking down silos and liberating manpower to realize cost reduction and efficiency through data drive

Enterprise managers do not need to repeatedly count the data of various departments, and workers do not have to stroll through the workshop again and again to check the equipment, now they only need a large screen, you can know from the factory park, workshop, equipment, three aspects of the real-time data in the process of running the product line and the operating situation.

Weiqiao digital twin green intelligent printing and dyeing factory through the ERP collection of equipment production data, the interface data with the big screen, model scenes, through the data storage, cleaning, analysis, visualization and application, to generate a production park overview, workshop production lines and important individual equipment to show three major digital twin scene, focusing on presenting the park data, including:

Production Data

Such as water, electricity, steam, natural gas, etc.

Production data

Such as the target production of the current day, production in the last six months, sales in the last six months, etc.

Equipment status

Such as order information, machine status and early warning monitoring in the workshop machine, etc.

The factory realizes “all-weather, all-round, all-process” data control, gives full play to the platform's data-driven advantages, combines the decision-maker's management data with multi-dimensional analysis, and effectively guides the factory's production and operation process to improve the factory's ability to make timely deliveries, discover problems in production in a timely manner, avoid waste of resources in the production process, and improve the management efficiency.

For workers, they only need to realize the roaming inspection of the workshop through the big screen, view the order information and equipment production information parameters that are being processed by the equipment, and monitor the order production of various equipment, which can effectively reduce both production costs and personnel efficiency.

Digital twin to help green low-carbon to provide sustainable development ideas

The construction of Weiqiao's digital twin green intelligent printing and dyeing factory provides enterprises with more scientific technical means and intelligent solutions, and promotes the green development and sustainable development of enterprises.

The application of digital twin technology can control the production process more accurately, monitor energy consumption in real time, reduce resource waste and energy consumption, improve production efficiency and product quality, so as to realize the goal of sustainable development and green development. This is in line with the development concept of “green, low-carbon, recycling, sustainable” put forward by our government, and also provides the ideas and direction of sustainable development for other industries.

Diversified Branding Methods One-click Switching to Meet Different Audiences

In order to enhance the effectiveness of the exhibition for the government, textile printing and dyeing enterprises and news media, Weiqiao Digital Twin Green Intelligent Printing and Dyeing Factory has deployed two sets of video promos and audio content on the homepage to showcase the brand image and product visibility. The content can be flexibly switched according to the different needs of the visiting audience, thus providing visitors with a better experience.

Fulima cloud Digital Twin-driven Industrial Internet Platform

Weiqiao Digital Twin Green Intelligent Printing and Dyeing Factory is built based on Fulima Cloud Platform as the technology base, which is a service-oriented manufacturing demonstration platform recognized by the Ministry of Industry and Information Technology of the State, and is committed to effectively assisting enterprises to base on manufacturing and integrate into the service through digital technology, improving the manufacturing efficiency and product service capability, reshaping the manufacturing value chain, and promoting the transformation of manufacturing enterprises to service-oriented manufacturing.

The platform includes J3D digital twin development platform, RBI business intelligence development platform, model intelligence lightweight platform and application low-code development platform, supporting Web digital twin, digital decision-making application online development. At the same time, the platform builds an open industrial Internet technology service system, covering a series of products and technology solutions such as Internet of Things, data platform, digital twin application development, algorithm services, etc., to create an industrial Internet industrial ecology with abundant resources, information sharing and win-win cooperation, and to help enterprises in the digital transformation and upgrading of the whole value chain from the three dimensions of digital marketing, digital production, and digital management and control.

Our Official WeChat

Our Official WeChat