With the rapid development of the mining industry, mining operations management exposed safety production, standardized operations and other issues are more and more, the emergence of related issues to the development of mining enterprises, bringing a lot of uncertain risks, how to achieve efficient and safe mining operations has become the focus of mining enterprises. The development of a new generation of information technology is important to promote the digitization of the mining industry, based on the Fulima cloud platform to create a smart mine system, can effectively promote the digital transformation of mining enterprises from production, operation, control and other aspects.

ntelligent mine system, based on digital twin, integrates mine environment, equipment, vehicles, materials, personnel and third-party system data to realize the supervision and management of all elements of the open-pit mine; integrates AI recognition algorithms, detects safety problems in time through video monitoring and testing, and reduces the frequency of safety accidents; integrates mine business systems, builds an integrated portal, establishes an internal data sharing system, and realizes the standardized management of mine business. Standardized management.

Focusing on the five key aspects of mining operations, such as tasks, production, safety, equipment and training, the company builds five centers, namely, the Production Control Center, Safety Management Center, Equipment Overhaul Center, Intelligent Training Center and Process Management Center, to achieve comprehensive control over the mines.

Production Control Center: One Map View of the Whole “Mine”

The intelligent mine system is oriented to production site management, driven by digital twin, and digitally maps the mine environment, terrain, equipment, personnel, road network and other elements of the situation to restore the production site. At the same time, the system can also combine the data of front-end intelligent sensing equipment and integrate the data of existing systems to realize the comprehensive monitoring of the entire elements of the production site, such as mine production, equipment, personnel, transportation, environment, energy consumption, etc., and provide real-time alarms for abnormal events, so as to realize the effect of “mine” in a single map, thus enhancing management efficiency and reducing safety risks.

Safety control center helps monitoring and intelligent warning of irregular operation

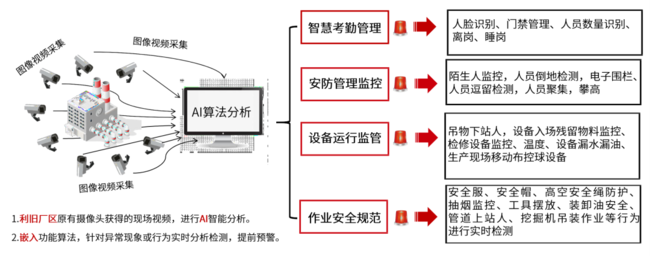

Relying on AI visual analysis technology, the Safety Control Center monitors and intelligently warns production safety management. The center covers a variety of applications, taking advantage of the original cameras in the plant, involving four major categories: intelligent attendance, security management monitoring, equipment operation supervision, and operation safety specification.

Once an abnormal situation occurs, the safety control center will push alarm information to the relevant personnel via PC and mobile terminal so that timely processing can be carried out. By clarifying the way of pushing alarm information, the center is able to form intelligent analysis charts to better show the results of the work of the safety control center.

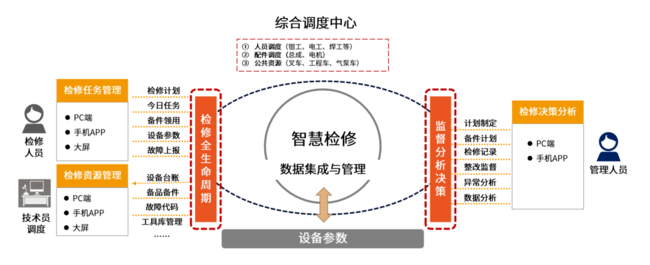

Equipment Overhaul Center Equipment Overhaul Full Life Cycle Management

The Equipment Overhaul Center is oriented to the full life cycle management of equipment overhaul process in the case of equipment item repair, overhaul, critical failure, maintenance, etc. The center integrates the existing equipment and customizes it to meet the requirements of the equipment. The center integrates existing equipment and carries out customized development, uses digital twin technology to realize one map management of equipment, and at the same time intelligently generates all kinds of reports, and warns the equipment according to the life span and operating hours of the assembly parts, so as to assist the management personnel in supervising, analyzing, and making decisions on the maintenance management.

Intelligent Training Center Virtual Simulation to Improve Teaching Quality

Intelligent mine system through the introduction of intelligent wearable equipment, the realization of equipment virtual simulation training, for mining equipment related to the vehicle, chassis, engines, hydraulics, electrical and other systems, such as the structure of the product, faults and typical cases of disassembly, simulation and maintenance, construction of engineering vehicles virtual simulation simulation training system, to enhance the effectiveness of teaching and training, and to reduce the technical threshold.

# Theoretical cognition

Provide theoretical knowledge learning

Provide structural cognition, working principle and other content learning.

#Simulation training

Provide operation training of various subjects

Provides training on comprehensive scenarios

#Examination and Evaluation

Provide theoretical assessment with randomized subjective questions

Provide task-oriented operational assessment

Process Management Center Lean Operation Management

Integrate the approval process through digital means, realize the management of corporate attendance, assets, contracts, files, supervision, labor protection, performance and other one book, online offline business, around the business value chain, open up process silos and business breakpoints, through the establishment of a standard approval mechanism, the establishment of a complete process from the beginning of the business to the end of the business, the realization of the company's collaborative network and lean operations, reduce manual duplication of work, and Enhance management capabilities.

Fulima cloud platform Digital twin-driven industrial Internet platform

Fulima cloud platform is a service-oriented manufacturing demonstration platform recognized by the Ministry of Industry and Information Technology of the People's Republic of China, which is committed to effectively assisting enterprises based on manufacturing and integrating services through digital technology, improving enterprise manufacturing efficiency and product service capabilities, reshaping the manufacturing value chain, and promoting the transformation of manufacturing enterprises into service-oriented manufacturing.

The platform includes J3D digital twin development platform, RBI business intelligence development platform, model intelligence lightweight platform and application low-code development platform, supporting Web digital twin, digital decision-making application online development. At the same time, the platform builds an open industrial Internet technology service system, covering a series of products and technology solutions such as Internet of Things, data platform, digital twin application development, algorithm services, etc., to create an industrial Internet industrial ecology with resource enrichment, information sharing, and win-win cooperation, and to help enterprises in the digital transformation and upgrading of the whole value chain from the three dimensions of digital marketing, digital production, and digital management and control.