Increase in model volume, use and maintenance become less efficient;

Different formats of various software models make deployment difficult;

The steps of lightweighting are cumbersome and require professional talents;

Poor model accuracy or interactive animation effect after compression;

......

The rapid development of the digital economy has led to the widespread application of 3D models in industrial manufacturing, urban buildings, energy control, etc., and the reduction of costs and increase of efficiency in various fields has been realized through digital twins.

However, with the increasing requirements of scene accuracy and business complexity, the above problems become a dilemma that enterprises have to face.

Enterprises need to streamline and transform their models on the premise of ensuring that model accuracy and functionality remain unchanged, scene performance is smooth and business logic is accurate. For this reason, Fulima Cloud officially launched the Voltium Code - Model Intelligence Lightweight Platform.

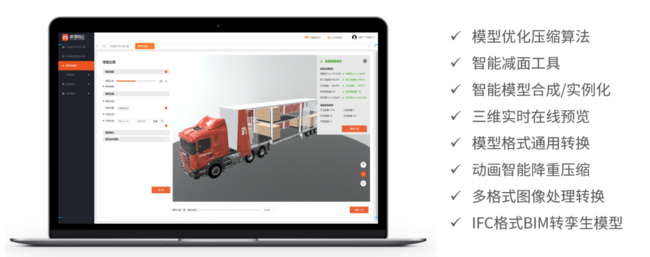

Fulima Code - Model Intelligent Lightweight Platform is Jerei's independently developed online intelligent model lightweighting and format conversion tool platform, which allows users to automatically realize model lightweighting and universal format conversion through one-click processing, achieve rapid model matching with 3D engines, and improve the real-time performance of twin applications.

Optimize Model Online Model Lightweighting

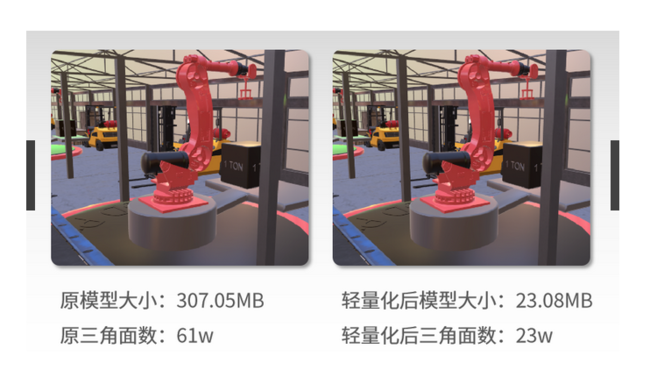

▲Model compression before and after the effect and size comparison

Model lightweighting is to streamline and compress the model volume as much as possible under the requirements of model accuracy, business function logic, etc., to realize its smooth application on the Web side.

VLM-Model Intelligent Lightweight Platform achieves nearly the same effect before and after model lightweighting, and compresses the model size by tens of times, effectively improving the smoothness of loading and model interaction in the digital twin scene.

The platform supports general model lightweighting (surface reduction, merging, compression, texture processing, animation processing, quantization, instantiation, etc.), as well as the lightweighting of BIM models in the common format IFC and the transfer of twin models. Different lightweighting strategies can be adopted for different types of models:

Model surface reduction

It is suitable for reducing the surface of fine models such as mechanical equipment, games, home decoration, etc. to preserve the effect. Preserve the layers, mesh objects, textures, UVs and animations of the original model, and automatically control the reduction ratio to ensure the effect.

Model Compression

Suitable for lightweight processing of models with large model data but need to retain details, such as park buildings, factories, machinery and equipment. Preserve the original model's layers, mesh objects, textures, UVs and animations, and perform lossless compression of geometric data.

Model Synthesis

Applicable to all industry application scenarios, for pure display parts of models of buildings, workshops, production lines, city parks, mechanical equipment, etc. that do not need to be disassembled and animated, merge and optimize them to greatly improve rendering efficiency. Merge models with the same material, retaining the texture, UV and animation of the original model.

Fast Adaptation: One-click model format conversion

Lithium Code - Model Intelligent Lightweight Platform operates online, allowing users to instantly convert model formats after uploading a model, without the need to download a client.

It applies a variety of advanced modeling algorithms to preserve model layers, animations, materials and other geometric data to ensure the conversion effect.

The platform supports the conversion of GLB, OBJ, STL, GLTF, FBX, 3DS, IFC and other mainstream model formats, and converts the model into a common model format for the Web side, which can be applied to the Web side of the twinning engine, expanding the application scenarios of the model.

WYSIWYG (What You See Is What You Get) Intelligent Optimization Real-time Acquisition

▲Visualization and Configuration

When the user applies the model intelligent lightweight platform to process the model online on the Web side, the model rendering status and compression data can be viewed in real time, which is convenient for the user to debug in a timely manner. At the same time, the platform supports offline deployment services, which is convenient for users to apply in different scenarios.

In addition, the platform also has the ability to view and process general BIM models, and users can realize model management through the model library.

Model lightweight in the enterprise, technology, manpower, carrying capacity, model application scenarios will be effectively enhanced:

Reduce the technical threshold: no need for graphical algorithm development, professional modeling personnel, visual configuration panel provides default parameters, one-click operation WYSIWYG.

Reduce labor cost: Reduce modeling manual mechanical surface reduction, synthesis, image compression and other work, improve the efficiency of 3D modeling.

Enhance project carrying capacity: model surface reduction, texture compression, animation weight reduction, model quantization, model synthesis, model compression, all-around optimization processing, optimize loading and rendering performance, and enhance the carrying capacity of the twin project.

Multi-platform docking: automatic universal format conversion of the model, opening up the 3D engine and various types of modeling, 3D platform model channel.

In the future, the platform will continue to iterate and upgrade model construction, model assembly, model fusion, model validation, model correction, model management, etc., to comprehensively improve the smooth application experience of the model, so as to realize the enterprise digital twin project to reduce costs, increase efficiency, improve the quality of cuts.